Mid-2017, I had upgraded my first Printrbot with metal parts, and I was looking for some cool projects to work on and picked up this book

My son was fascinated with the RC tricycle project, so we decided to give it a try.

The partially-assembled RC car.

The design wasn’t perfect - the original design used used a propeller motor and speed controller from a drone, so it had almost no low end torque and a /very fast/ top speed (also, no reverse!). Heat from the motor eventually melted the 3D printed part that held the motor.

That said, though, it was an impressive design - everything could be 3D printed. There was even a really cool ninjaflex suspension system. It was fun to push the limits of my 3D printer, and we had a lot of fun smashing this car up on the sidewalk a few times.

I kept the RC components around because I knew I wanted to roll them into another project, but I didn’t have them design skills at the time to pull it off. This summer I felt like I was ready to put something together. We decided to make a boat.

Key components were:

- ESC Car Speed Controller

- Flysky Transmitter

- Waterproof Receiver

- Brushless Motor

- Boat Propeller Shaft

- 3mm to 5mm coupler

- Boat Propeller

- Servo Motor

- LiPo Battery (and Charger)

My goal with this project was to create an entire assembly in CAD, and then build and use the object.

I was not interested in falling down a rabbit hole related to boat hull design, etc., and I did not want to spend money on new components if I could help it.

The design

With these constraints in mind, I modeled all the electronic parts, designed a very basic hull, and then the rest of the mechanical design fell together pretty quickly.

My first attempt had the shaft exiting the back of the boat at a 45° angle, but I ended up changing this to a design that had the shaft low and parallel to the waterline instead.

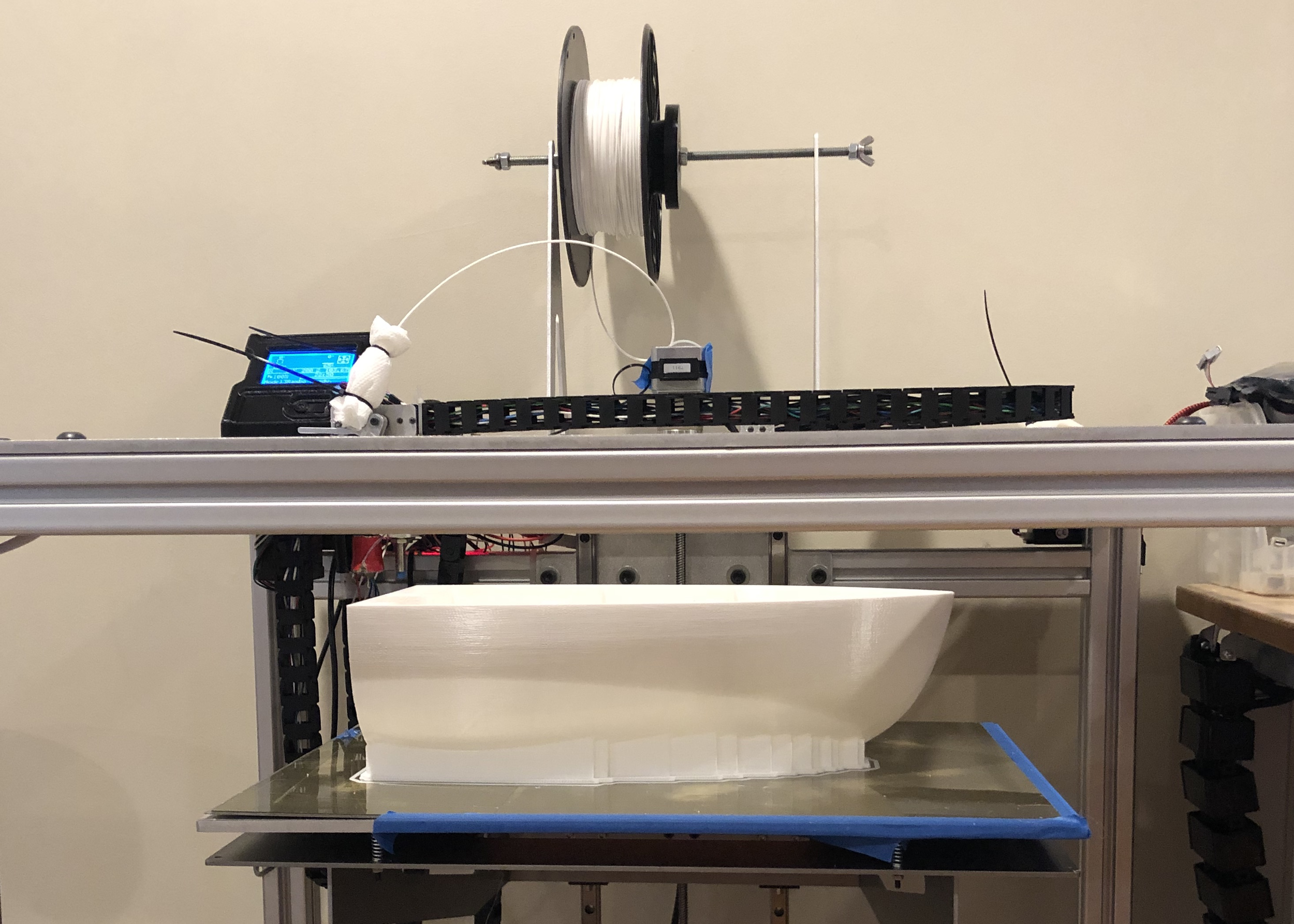

Successful print of the boat hull on my big printer

The boat hull was the first part, and naturally the hardest to make. I 3D printed it as a single piece and then coated the outside with Total Boat resin to make it stronger and watertight.

I knew from the RC car project that the motor would throw off a lot of heat, so I mounted the motor on a plywood sandwich held between two 3D printed parts.

The wood parts were laser cut, and I had great success with threaded heat inserts into the printed parts. Everything was connected with M3 and M4 bolts.

The rudder hinge was made with two sizes of K&S hobby brass tube that fit pretty tightly together. I heated up the brass and pushed it into the 3D printed parts, and dropped a 1/4” washer between the rudder and the boat hull, and everything turned smoothly.

The rudder arm was 0.51” stainless steel aircraft safety wire. I adapted the design from the very helpful instructions here.

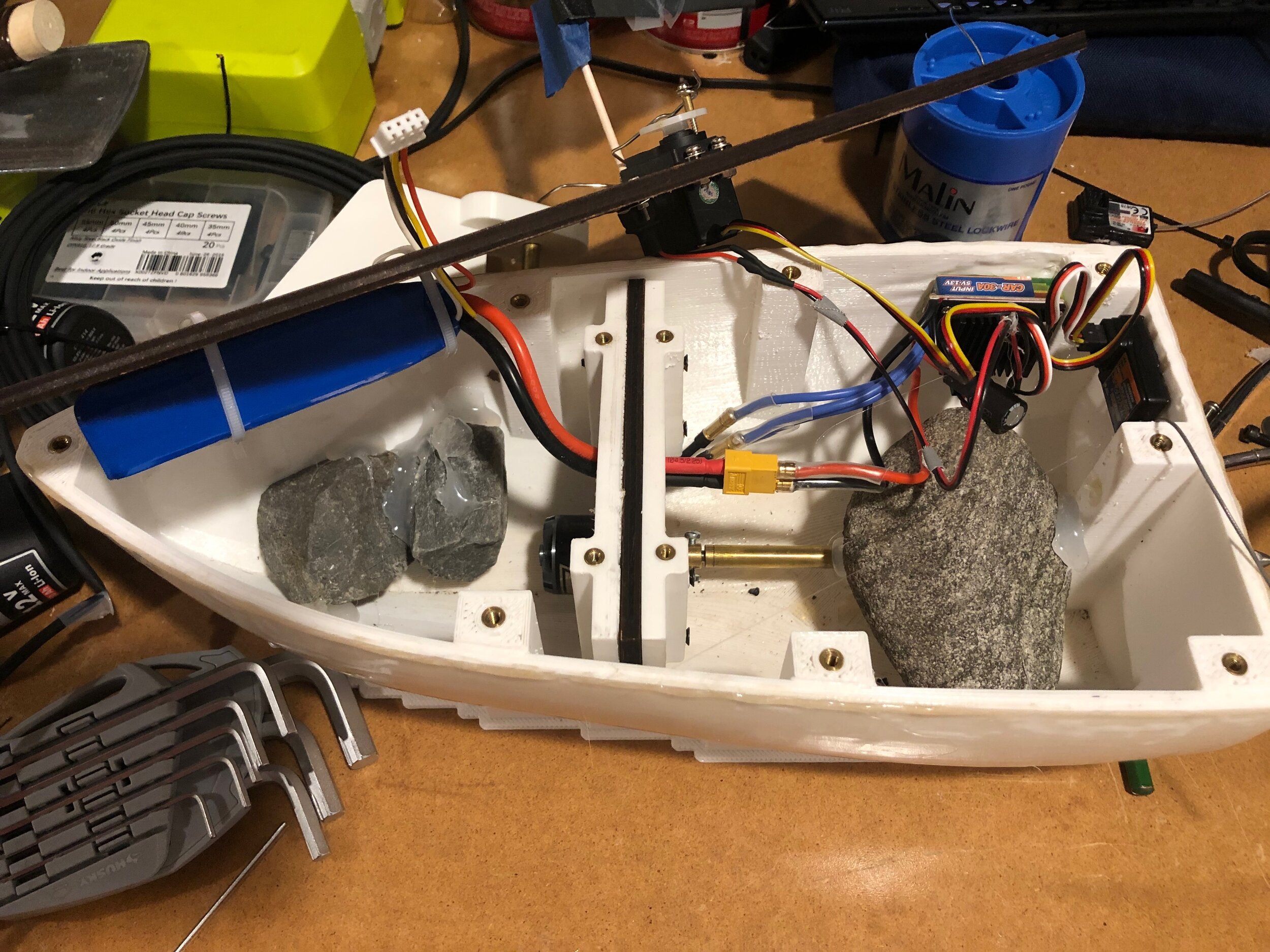

Our first venture with the boat on a local pond was not successful. We had not fully sealed the spot where the shaft enters the hole, so the boat quickly took on water. Also, we learned balance and ballast are important concepts for a boat of any size; our design required weight to hold the propeller below the water line, and that weight needed to be balanced carefully so the boat did not tilt in the water.

We fixed the leak with a little silicone sealant, and few rocks hot-glued inside the hull balanced everything up.

Rocks balancing the boat

The water inside the hull fouled the RC receiver, so I had to replace this part (the linked part is the new one I purchased, that claims to be waterproof). A few part swaps later, we were ready to set sail again.

The boat wasn’t as fast as we hoped it would be, but it runs, and we’ve had a lot of fun designing and driving it. In all, a good project and a good experience designing and then building something.

If I were to continue with this design, I’d definitely come up with a smarter hull shape, and make sure I had decent waterproofing on the whole boat. I achieved my goal with this project, and right now, have other projects that are more interesting to me.